https://www.nature.com/articles/s41467-024-53341-y

https://www.cas.cn/syky/202410/t20241029_5037676.shtml

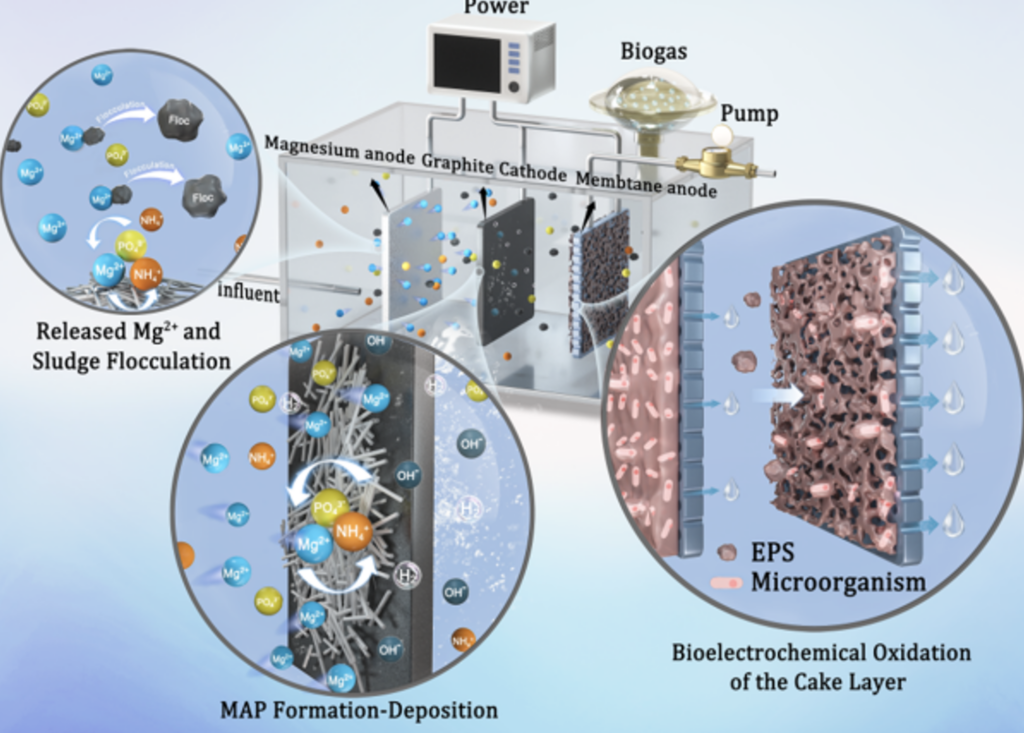

The team of Qu Jiuhui at the CAS Ecological Environment Research Center of the Chinese Academy of Sciences and an academician of the Chinese Academy of Engineering, has made progress in electrochemical anaerobic membrane bioreactors. Simultaneous recovery of resources and energy in sewage treatment is an important direction for the green and low-carbon transformation of the water industry. Anaerobic membrane bioreactor (AnMBR) has the advantages of low energy consumption, high organic load and effluent quality, and has application prospects in the field of sewage resource utilization. However, the traditional AnMBR membrane is seriously polluted and cannot recover ammonia nitrogen and phosphorus in wastewater. The team created a resource recovery electrochemical anaerobic membrane bioreactor (eRAnMBR). The eRAnMBR adopts a magnesium anode-conductive membrane dual anode and graphite cathode structure to achieve full recovery of carbon, nitrogen and phosphorus in wastewater and alleviate membrane fouling. Studies have shown that magnesium anode releases magnesium ions to combine with ammonia nitrogen and phosphate to form struvite; at the same time, the cathode hydrogen evolution reaction increases the local pH, which is conducive to the cathode deposition of struvite, thereby promoting the separation of struvite and sludge to achieve in-situ recovery.

The team analyzed the effect of regulating the filter cake layer structure on the membrane surface on the mitigation of membrane fouling and the role of the electron transfer pathway in promoting methane generation. The study found that the released Mg2+ increased the size of sludge flocs, reduced the adhesion between sludge particles and the membrane surface, and reduced the proportion of hydrogen bonds in the secondary structure of extracellular polymer proteins, thereby weakening the formation of the gel layer and making the filter cake layer structure loose and porous. At the same time, the electrochemical reaction strengthened the direct electron transfer between species and enriched the methane production pathway, and the purity of the generated methane was increased to 94%.

Cost estimates show that if the methane power of eRAnMBR is recycled and utilized, the power and electrode consumption costs of the reactor can be covered. This reactor has the advantages of simple process, less membrane maintenance and low carbon footprint, providing a new technical option for the next generation of wastewater treatment.