https://www.cas.cn/syky/202512/t20251218_5092814.shtml

https://pubs.acs.org/doi/10.1021/acs.est.5c14410

Lignocellulose biomass, such as corn stalks, is one of the most abundant agricultural waste resources on Earth and is considered a key candidate raw material for building a sustainable bioeconomy. However, its industrial utilization has long been constrained by the bottleneck of “low carbon utilization efficiency.” Taking cellulosic ethanol as an example, nearly one-third of the carbon atoms are lost as carbon dioxide during ethanol fermentation. Furthermore, incompletely fermented organic matter remains in the fermentation broth, resulting in a cumulative carbon loss of up to 60%.

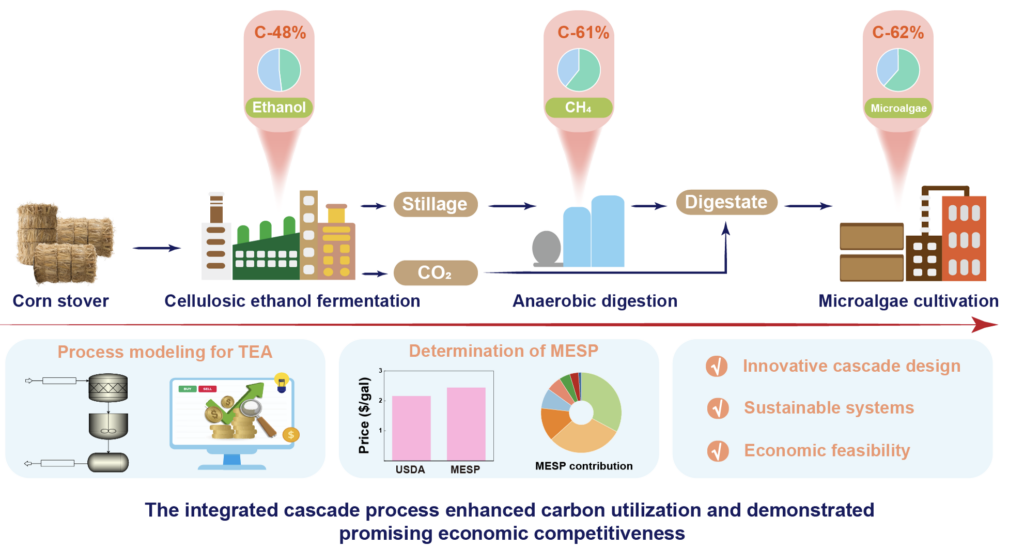

The CAS Chengdu Institute of Biology and others propose a cascaded utilization route for lignocellulose biomass carbon resources. They constructed a three-in-one integrated cascaded process: “cellulosic ethanol fermentation—anaerobic digestion of ethanol waste broth—biogas slurry coupled with ethanol tail gas cultivation of microalgae,” achieving full-chain capture and high-value conversion of lignocellulose carbon resources.

The researchers utilized metabolically engineered brewer’s yeast to efficiently ferment pretreated corn stalk hydrolysate with mixed sugars, effectively overcoming the technical bottleneck of traditional strains’ inability to utilize pentoses. The resulting ethanol waste liquid (containing residual organic matter) was anaerobically digested to produce methane, achieving secondary recovery of residual carbon resources. The biogas slurry from anaerobic digestion, along with carbon dioxide captured during ethanol fermentation, served as a microalgae culture medium, achieving both carbon biofixation and nutrient recycling. Through this integrated cascade process, the carbon utilization rate of lignocellulosic biomass, represented by corn stalks, increased from 48% in traditional processes to 62%.

Building on this foundation, researchers further conducted industrial-scale simulations and techno-economic analyses, constructing an industrial-scale integrated process model capable of processing 2000 tons of corn stalks per day. Analysis showed that the lowest ethanol price for this route could reach $2.44 per gallon, approaching current market levels. Simultaneously, raw material costs and cellulase costs were identified as the main cost drivers, providing a clear direction for subsequent process optimization and industrialization.