https://www.cas.cn/syky/202512/t20251202_5090976.shtml

https://doi.org/10.1002/adma.202517928

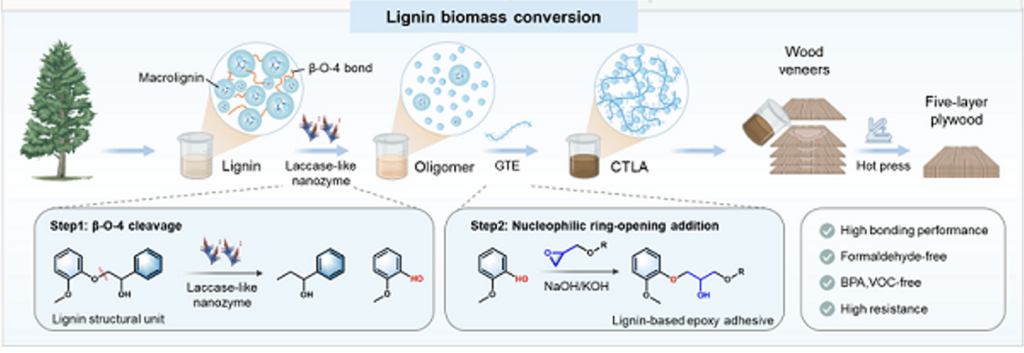

Converting lignin into high-value-added chemicals or materials is of great significance for the high-value utilization and sustainable development of biomass. Nanozymes, as nanomaterials with enzyme-like catalytic activity, combine the high efficiency of natural enzymes with the stability of nanomaterials, providing a new pathway for the green degradation of lignin.

A research team from the CAS Institute of Biophysics, inspired by the multi-copper active center of natural laccase, proposed a “spin engineering” strategy which involves precisely controlling the spin state of copper in two-dimensional metal-organic framework (MOF) nanozymes, breaking the constraint between activity and selectivity, and achieving efficient and directional degradation of lignin. Based on this strategy, the research team further developed a high-performance, environmentally friendly lignin-based epoxy adhesive.

They prepared a two-dimensional copper-based MOF (COHB) and constructed a series of nanozyme derivatives with different copper spin states using redox treatment and ligand exchange strategies. The optimized nanozyme (COHBLO) simulated the multi-spin synergistic catalytic mechanism of natural laccase, with a maximum reaction rate 70 times that of natural laccase and a specific activity 5.14 times higher.

The research team further developed an integrated pathway from lignin degradation to adhesive preparation. Using lignin fragments rich in active phenolic hydroxyl groups generated from COHBLO degradation as raw materials, a nucleophilic ring-opening addition reaction was carried out with an epoxy source (glycerol triglycidyl ether) to prepare a lignin-based epoxy adhesive (CTLA) with a dense cross-linked network structure. Experimental results showed that this adhesive exhibited excellent mechanical properties in wood bonding, with shear strength significantly superior to commercial phenolic resins and epoxy resins, and no formaldehyde release. Meanwhile, CTLA exhibited good water resistance, solvent resistance, extreme temperature resistance, and flame retardant properties.