http://en.people.cn/n3/2025/0702/c90000-20334871.html

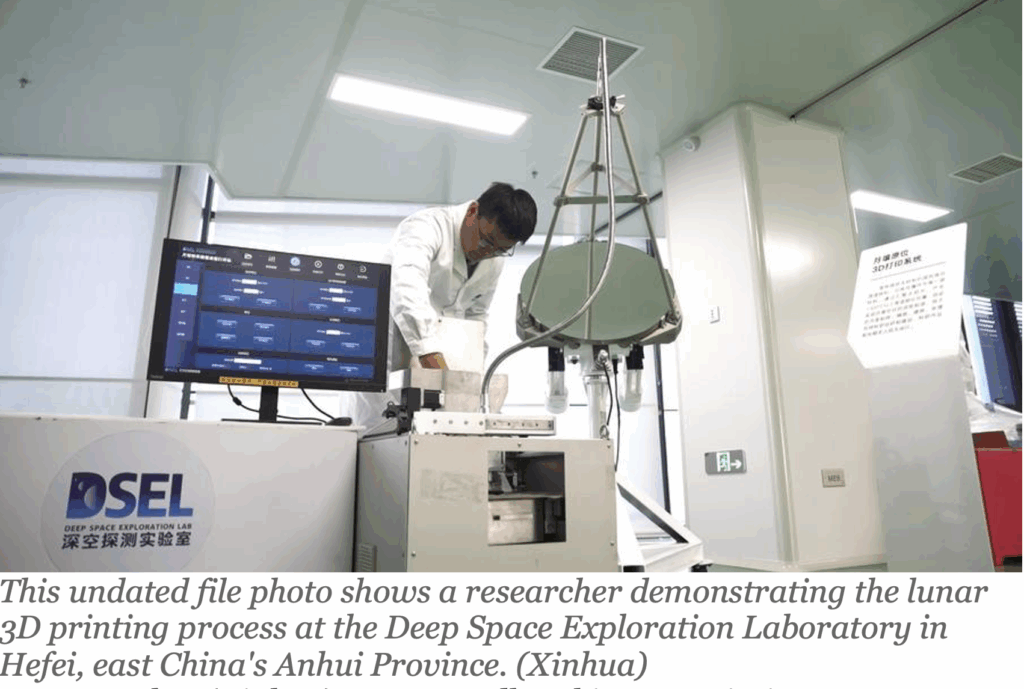

The Deep Space Exploration Laboratory in Hefei, Anhui Province, has successfully prototyped a lunar regolith 3D printer that eliminates the need for Earth-sourced construction materials. The system uses a high-precision reflective concentrator and flexible fiber-optic energy transmission to achieve temperatures hot enough to fuse lunar regolith. Also among the printing system’s key innovations is flexible manufacturing, which enables brick production and the customized molding of complex structures.

A preliminary test of the prototype has been completed on the ground surface. Tests of its ability to melt and form lines, surfaces, bodies and complex structures have also been completed, and tests of the technical feasibility of the prototype’s solar concentrating technology, optical fiber bundle energy transmission and lunar regolith melting system have been systematically completed.

The prototype could manufacture lunar regolith structures, supporting the construction of lunar roads, equipment platforms and buildings, and enabling large-scale, sustainable lunar exploration and resource utilization. It also has mastered key technologies for lunar energy capture and material extraction, laying the technical foundations for the construction of lunar energy systems.

The lab — also known as Tiandu, named after one of the three main peaks of the province’s Yellow Mountain — is a national-level scientific research platform built by the China National Space Administration, the Anhui provincial government, and the University of Science and Technology of China. Since its official launch in June 2022, Tiandu has provided robust support for the successful implementation of major projects such as the Queqiao-2 relay satellite and the Chang’e-6 lunar mission, which returned humanity’s first-ever sample from the far side of the moon.

Looking ahead, the lab is developing the world’s first Mars sample research facility and is inviting collaboration.