https://www.chinesechemsoc.org/doi/10.31635/ccschem.025.202404851

https://www.cas.cn/syky/202503/t20250325_5059934.shtml

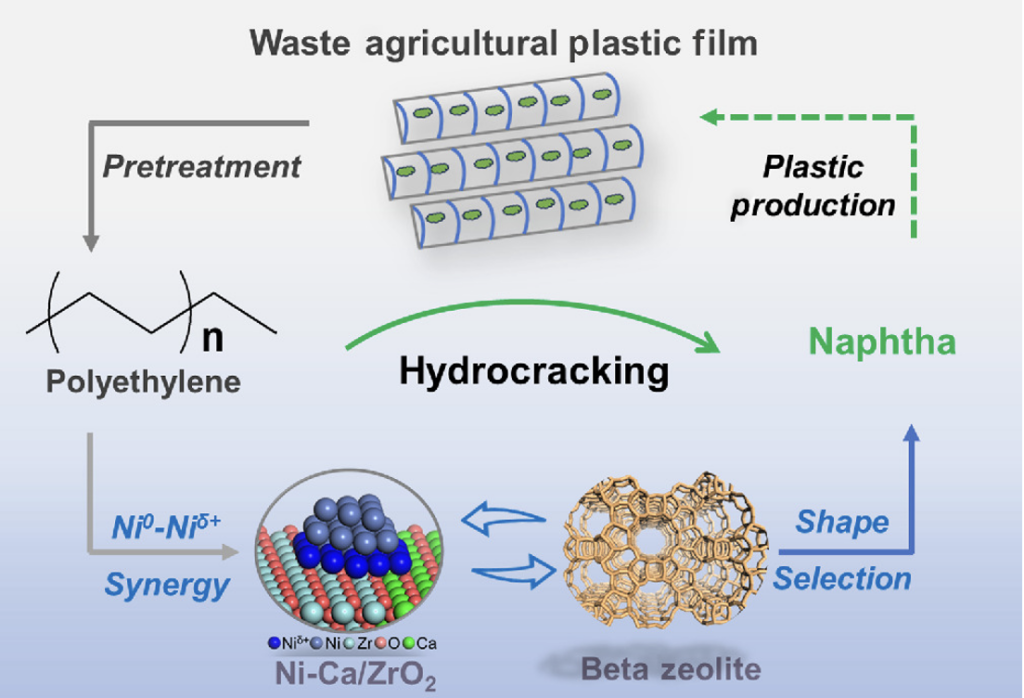

Researcher at the CAS Shanghai Advanced Research Institute have developed a procedure to upgrade waste plastics to produce naphtha and ethylene monomer through steam cracking, and then build a recycling and closed-loop utilization system for waste polyethylene plastics. On this basis, the team designed a non-precious metal Ni-based catalyst to achieve the selective hydrocracking of real waste plastics .

Their study showed that after pretreatment of waste polyethylene plastics to remove impurities, Ni-Ca/ZrO2 and Beta molecular sieves could be used as catalysts. Under the conditions of 250℃ and 3MPa hydrogen, the naphtha yield was 87%, and the selectivity of C5-C11 alkanes reached 98%. The electron transfer of Ni is conducive to the generation of Niδ+ species, which improves the catalytic hydrogenation activity of olefin intermediates, while the micropores of Beta molecular sieve can screen out low-carbon alkanes, thereby generating naphtha products with high selectivity.

Taking the recycling of waste polyethylene plastics as a scenario, the study found through life cycle assessment and technical and economic analysis that compared with incineration power generation, the strategy of making naphtha from waste plastics can reduce carbon dioxide emissions by 82% and achieve energy self-sufficiency; when the scale exceeds 10,000 tons/year.