http://en.people.cn/n3/2024/0613/c90000-20180649.html

A photo of the Chinese Chang’e-6 probe’s lander-ascender combination on the far side of the moon has captured a historic moment in human lunar exploration. The photograph was taken by a mini rover that was carried to the moon by the Chang’e-6 mission.

The probe has collected samples from the moon’s far side and is currently in lunar orbit, awaiting the optimal time for its return journey. The autonomous, intelligent mini robot was attached to the lander during the mission’s journey to the moon and its moon landing. After Chang’e-6 collected the samples on the far side of the moon, the mini rover autonomously detached from the lander, moved to a suitable position, selected an ideal angle for the photograph, and then captured the image.

At approximately 5 kilograms, the mini rover is much lighter than Yutu, China’s first lunar rover, which was roughly equivalent in weight to two adults. Despite its compact size, the mini rover is highly capable and has significantly enhanced autonomous intelligence.

The lunar probe Chang’e-6 had completed sample collection in the Antarctic-Aitken Basin on the far side of the moon on June 2 and 3 and sealed and stored the samples in a storage device in the ascent module. People’s Daily reported.

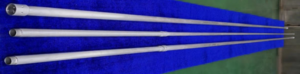

Two methods were used to collect samples this time: drilling and surface sampling. The aluminum-based composite drill pipe and lightweight aluminum alloy coring pipe developed by the Institute of Metals, Chinese Academy of Sciences.

The sampling device used for drilling has a three-layer structure with a design length of 2.5 meters. The outermost layer is a drill pipe that can drill while rotating, and next to it is a coring pipe. The outside of the coring pipe is covered with a coring bag, and as the drill drills downward, the coring bag also moves downward with it. The lunar soil obtained by drilling is pushed into the bag. This process is somewhat similar to putting on a sock, and after sampling, the coring bag is rolled up to place the soil into the drilling temporary sealing device.

The outer drill pipe is made of silicon carbide particle reinforced aluminum matrix composite and is a key component of the lunar drilling sampling mechanism. Through the use of large billets of aluminum matrix composite and multi-pass deformation processing methods, The high-strength aluminum matrix composite extrusion rods, forgings and thick-walled pipes have significantly improved the performance and stability of the material.

The coring pipe for soil collection is made of two lightweight dissimilar aluminum alloys. In order to meet the extreme environment of soil collection on the far side of the moon, the team has overcome a number of technical challenges and developed an outer sheath and core pipe with a lightweight structure.