Qingdao Energy Institute improve cellulose processing by molten salt hydrate pretreatment

more insights

https://www.cas.cn/syky/202602/t20260226_5102870.shtml

https://doi.org/10.1186/s40168-026-02339-3

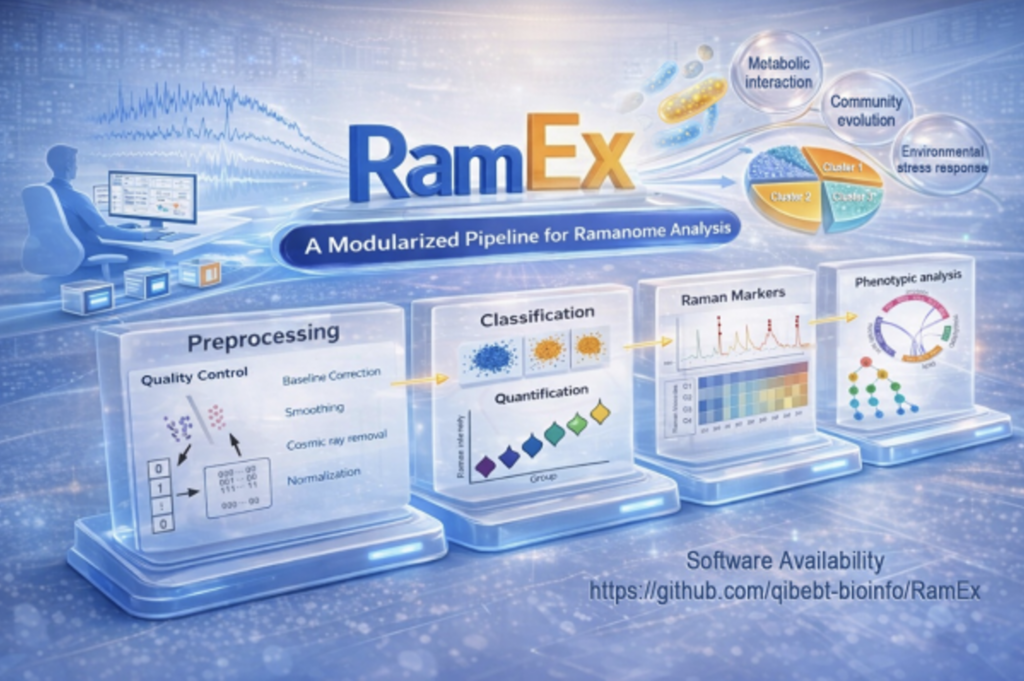

A research team at the CAS Qingdao Institute of Bioenergy and Bioprocess Technology has developed RamEx, an integrated analysis framework for Ramanome big data. This platform, tailored to the characteristics of Raman spectroscopy data, establishes a one-stop workflow from data reading and standardized preprocessing to downstream data mining, centered on automated quality control algorithms and efficient parallel computing processes. It also demonstrates a systematic analysis of microbial metabolomical heterogeneity and metabolic pattern differentiation at the single-cell level.

Raman genomics deep analysis can track the dynamic changes in the composition of macromolecules such as lipids, proteins, and nucleic acids in different cells, thus revealing the differentiation and succession patterns of microbial metabolic states at the population scale with single-cell precision. This provides new research ideas and technical pathways for understanding the functional organization and environmental adaptation mechanisms of complex communities.

http://english.cas.cn/newsroom/research-news/202602/t20260224_1151116.shtml

https://link.springer.com/article/10.1186/s40168-026-02339-3

Scientists from the CAS Qingdao Institute of Bioenergy and Bioprocess Technology have developed a novel computational tool, RamEx, designed to resolve the computational bottleneck in high-throughput microbial Ramanomics.

RamEx streamlines the full Ramanomic analysis pipeline, from data preprocessing and automated quality control to advanced data mining. An Iterative Convolutional Outlier Detection (ICOD) algorithm tackles spectral noise in an unsupervised manner to dynamically identify and eliminate spectral artifacts, ensuring high-quality input for downstream analysis.

The platform’s performance was validated using diverse datasets, including pathogenic bacteria, probiotics, and yeast fermentation systems. Notably, RamEx successfully captured phenotypic heterogeneity in genetically identical yeast cells by detecting subtle metabolic fluctuations and tracking the dynamic accumulation of intracellular macromolecules, including lipids, proteins, and nucleic acids.

https://japanese.cri.cn/2026/02/21/ARTI1771656131487329

The “Zhifei,” China’s first commercially operational smart container ship, accurately docked at a berth at the automated wharf in Qingdao Port, using unmanned autonomous navigation mode. This marks the first time that China has achieved an unmanned operation of a container ship, including navigation, berthing, and operation.

After the “Zhifei” container ship arrived at its designated location, the vacuum suction cups installed in its vacuum automatic mooring system powerfully attracted the hull, firmly securing it to the berth in less than 30 seconds, without any manual mooring work. The terminal’s fully automated loading and unloading equipment then operated simultaneously, and China’s A-TOS (Atelier Terminal Smart Management System) and A-ECS (Analytical Equipment Control System) worked together to precisely coordinate equipment such as automated cranes and automated guided vehicles at millisecond speeds, completing the container loading and unloading process.

The Zhifei is equipped with smart navigation core system, and as China’s first smart cargo ship for commercial operation, it features three navigation modes: manned, remotely controlled, and unmanned autonomous navigation.

Back to …