http://j.people.com.cn/n3/2023/0602/c95952-20027001.html

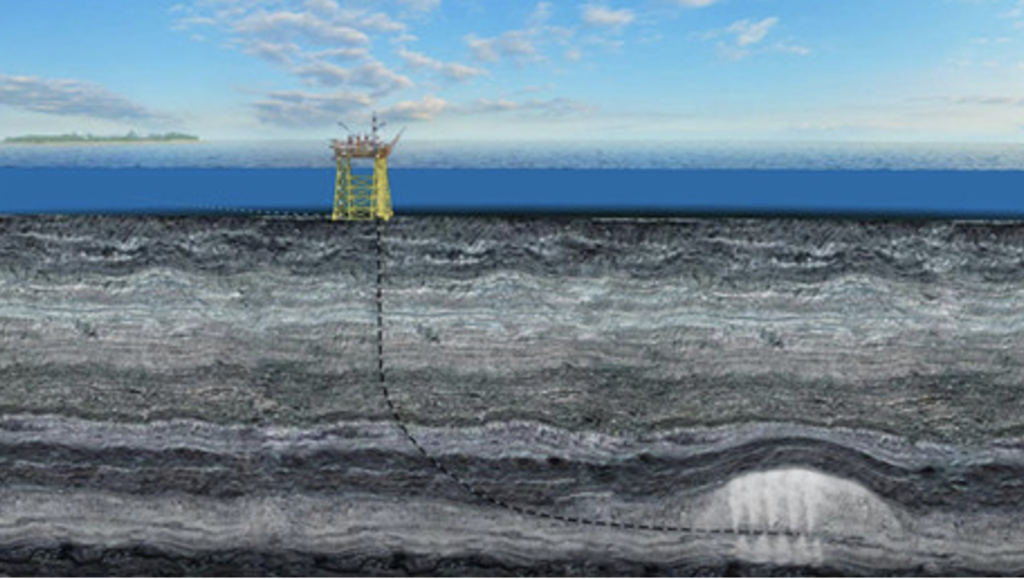

According to China National Offshore Oil Corporation (CNOOC), China’s first CO2 storage model project started operation on June 1 at the “Onping 15-1” platform, located about 200 km southwest of Shenzhen, Guangdong Province. Carbon dioxide (CO2) generated from oil field development is captured, separated, and pressurized until it reached a supercritical state of liquid/gas mixture, and then reinjected at a rate of about 9 tons per hour through a CO2 reinjection well into a saline dynamic layer over 800 meters on the seafloor 3 km from the platform. The formation where the CO2 is reinjected has a ‘dome-shaped’ geological structure. This geological structure is shaped like a giant overturned vessel and has natural sealing properties that allow for long-term stable storage of CO2. The project is capable of storing 300,000 tons of CO2 each year, and is expected to exceed 1.5 million tons in total. This is equivalent to planting nearly 14 million trees.

The Eunpyeong 15-1 platform is the largest offshore crude oil production platform in Asia, with a working water depth of approximately 80 meters, and a peak oil production rate of over 7,000 tons per day. The CO2 concentration of the associated gas from “Eunping 15-1” is as high as 95%. If developed in the normal way, CO2 will be released along with crude oil to the surface, which will not only corrode offshore platform facilities and subsea pipelines, but also increase China’s CO2 emissions. Therefore, China Sea Oil implemented a CO2 storage model project in the “Onping 15-1” oil field.