https://www.cas.cn/syky/202305/t20230518_4888125.shtml

The research team of Dr. Feng Jiao, Xiulian Pan and Xinhe Bao at the Dalian Institute of Chemical Engineering, Chinese Academy of Sciences has developed a new innovation in the direct conversion of coal to olefins via syngas, providing a proven scientific approach to the “see-saw” problem of high activity and high selectivity. The research results were published in the journal Science on May 19.

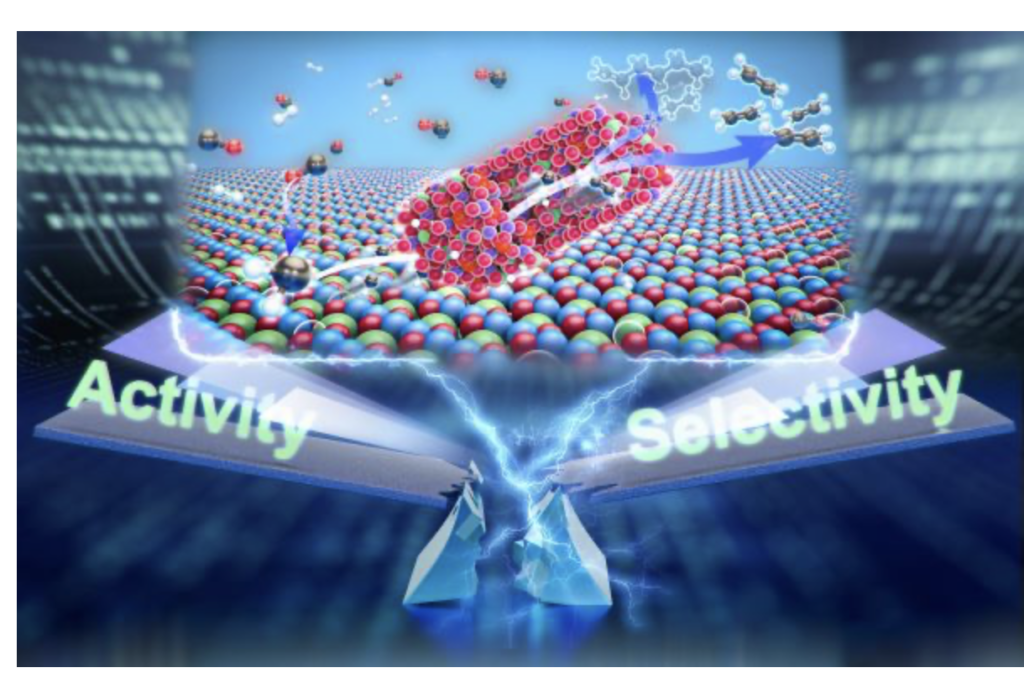

The group created a catalytic system (OXZEO) with a composite of oxide and molecular sieve with separated active centers. In this system, the activation and dissociation of the reactants carbon monoxide and hydrogen, as well as the generation of the active intermediate ethylene ketone CH2CO, take place on the surface of the oxide ZnCrOx, and the intermediate enters the molecular sieve pore channel by diffusion, and the subsequent reaction process of carbon-carbon coupling to olefin is realized in the restricted pore channel of the molecular sieve. The selectivity of low carbon olefins is as high as 80% at 17% carbon monoxide conversion, thus breaking the theoretical limit of 58%, which has been insurmountable for a century for the classical Fischer-Tropsch synthesis of low carbon hydrocarbons. The process eliminates the water gas conversion and intermediate product synthesis steps, and in principle creates a new pathway for coal conversion with low water consumption and low emissions. In 2016, the institute cooperated with enterprises to create OXZEO?-TO catalyst and completed an industrial trial in 2020 with an annual production of 1,000 tons of low-carbon olefins in the plant, which verified the feasibility of the process.

Since then, it was found that the existing molecular sieve active center not only catalyzes the primary reaction of converting intermediates to low carbon olefins, but also catalyzes the secondary reaction of over-hydrogenation of low carbon olefins to low value alkanes or over-polymerization to large olefins, so this common active center is like the fulcrum of a seesaw, and the selectivity of one end of the conversion rate is increased while the other end is decreased. Experimental results showed that accelerating the transfer and conversion of intermediates and reducing the occurrence of side reactions in the pore channel of molecular sieve are effective ways to untie this “entanglement”.

Based on a large number of experiments, the research group developed a metal germanium ion homocrystal substituted microporous molecular sieve (GeAPO-18), which maximizes the pulling ability of the molecular sieve pore channel to the active intermediates by increasing the density of Bronsted acid sites in the molecular sieve pore channel, and promotes the production rate of intermediates, while reducing its acid strength and reducing the over-addition of carbon-carbon coupling process. carbon coupling process. Under optimized reaction conditions, the catalyst achieves a one-way conversion of carbon monoxide of 85% while maintaining a low carbon olefin selectivity of >80% (up to 83%), achieving an international best low carbon olefin yield of 48%, more than double that of the first generation OXZEO catalyst.